If you’re already operating in the vehicle wrapping or graphics market, you’ll know exactly why it’s one of the biggest growth areas among graphic designers and the print industry. Recent statistics forecast substantial growth in the vehicle wrapping and personalisation industry, with a compound annual growth rate* of 21.8% from 2022 to 2030 to reach USD 25.49 billion by 2030, driven by the increasing demand for customised and visually appealing wraps.

https://straitsresearch.com/report/automotive-wrap-films-market*

Vehicle wrapping stands out as a powerful and visually impactful way to showcase anything from corporate branding and advertising to iconic designs and complete or partial visual overhauls.

So, what can you do to stand out in an increasingly competitive market? As print technology advances, so do the tools at our disposal, and one innovation that has been gaining traction in the vehicle wrapping industry is the use of Resin/Latex inks.

In this article, we'll delve into the benefits of these cutting-edge inks and why they’re the ideal print solution for creating stunning, durable, and customised vehicle wraps.

Benefits of Resin Ink Printing

Best Digital Signs’ tribute to Peter Brock’s 1979 Bathurst Winning A9X Holden Torana featuring highly detailed artwork to create a battered and worn look, as the car would have been after the race-winning ride.

It’s not at all uncommon for businesses to stick with what they know. However, just because something is tried, tested, and trusted doesn’t mean there aren’t other solutions worth exploring. Improvements in technology are made all the time and ink is no different. Solvent-based inks remain incredibly popular in the vehicle wrapping space due to their flexibility. If wraps are one of many applications you produce then eco-solvent is a great all-rounder, but if you want to pursue wrapping as a core business function then the TrueVIS AP-640 offers a new, exciting solution for your business to consider.

Here are some of the top reasons for considering Resin/Latex inks for vehicle wraps.

Vibrant Colour Reproduction

The TrueVIS Resin inks are celebrated for their ability to produce vivid and dynamic colours by delivering a heavier saturation than other Resin inks. The TrueVIS AP 640 resin printer has been praised in independent testing for producing the largest colour gamut for Resin or latex ink, as well as its exceptional image quality and colour-matching results.

“The AP-640 is the first 4-colour device that we have tested that has achieved 5-star status for colour accuracy.” David Sweetnam, Director of Lab Services, Keypoint Intelligence.

It’s the ideal device for creating eye-catching wraps that attract attention with unparalleled clarity. The AP-640 is a 4-colour machine, however, the high saturation TA inks compare particularly well, even against competitive 6-colour devices. The overall colour reproduction qualities make corporate colour matching much easier, particularly important for corporate branding fleet graphics.

Read this article for full details on the AP-640 earning the BLI 2024 Pick Award from KeyPoint Intelligence.

Rapid Turnaround Times

Rapid turnaround times can be the difference between securing your next big client or not being able to meet their needs. The TrueVIS AP-640 is engineered to deliver high-speed printing and finishing without compromising on quality. The innovative variable dot dual print heads are laid out in a staggered formation for exactly this purpose. The leading print head lays an optimiser to prepare the media surface so that the ink droplets from the CMYK print head can form a finer dot, resulting in more precise colour and images.

The dryer system is incredibly efficient, retaining the heat thanks to an advanced ‘air curtain’, so it uses less electricity than other systems. The AP-640 is also kinder to the print media than other dryers to ensure it keeps its integrity. It retains its print accuracy for longer as a result, important for precise alignment and longer prints. The prints exit the dryer at a low temperature and are ready for immediate lamination or finishing. The quick-drying Resin ink enhances productivity and ensures deadlines are met, giving your business a competitive edge.

Durability That Exceeds Expectations

A fully-wrapped race car designed by FunkeeFish

How long a vehicle wrap will last is crucial, considering the different environmental elements and levels of wear and tear they’re exposed to. Resin inks excel in durability, providing tough protection against UV rays, harsh weather conditions, and everyday use, while maintaining the print’s vibrancy.

Resin ink in the AP-640 performs very well when media stretch is required for an application, especially when printing cast vinyl for vehicle wraps and the challenging surfaces they present. When stretched to 200%, AP-640 prints retained more of their overall colour than competitor devices.

Laminating prints is essential for improving the durability of the wrap, adding an extra layer of protection against sunlight, scratches, and fading. Laminate adheres particularly well with TrueVIS Resin ink, ensuring optimal performance of the product and avoiding costs or inconvenience caused by ‘de-lamination’. With the media certification of the AP-640, you have the confidence that printed media will perform to specification.

The TrueVIS AP-640 is covered by Avery Dennison’s Integrated Component System (ICS) Performance Guarantee. The ICS Warranty Program offers additional assurance on media performance and compatibility, so you’re guaranteed consistent quality without defects when using their product.

Versatile Customisation

Mission Motorsport applying graphics to a car

Vehicle wraps are much more than canvasses for branding; they are platforms for individuality. Resin ink offers print businesses an expansive palette to work with, able to reproduce intricate designs, personalised graphics, and visually stunning wraps that surpass the client’s expectations.

The previously mentioned variable dot sizes help to produce improved print quality. Smaller dots optimise the finer detail and larger dots create flat, solid fills of colour. The capability to print variable dots in both smaller and larger sizes results in sharper finer detail and better large-area coverage. This results in exceptional print quality and vibrancy, even when printing at lower resolution.

The relatively thin ink layering of Resin ink means that the media surface finish is retained – matte media is printed matte, and gloss keeps a gloss finish.

Low Running Costs

Producing more output with less ink is an effective way of reducing running costs. Highly pigmented ink means less is needed to produce unparalleled image and colour quality.

Printing high-quality prints at lower resolution thanks to superior variable dot print reduces ink usage further and maximises printer productivity.

The variable dot piezo print heads used in the AP-640 are long-life. When coupled with Roland DG Care’s celebrated warranty packages, which cover the print heads and all components, there are considerable savings to be had over the lifetime of the printer.

VersaWorks 6, included when you purchase an AP-640, is a powerful, user-friendly RIP with several time-saving features, such as job grouping and multi-device management, designed to improve efficiency. Roland DG Connect is a machine monitoring app that also helps to streamline performance so that you get a return on investment as quickly as possible.

Environmental Responsibility

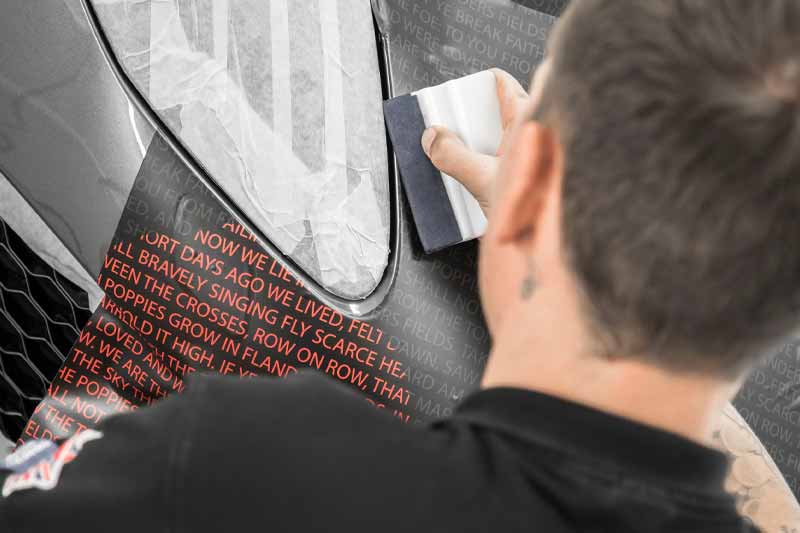

Chris Dunning of Elite Wrappers in the process of completing a truck wrap

GREENGUARD Gold certified Resin inks are recognised for being eco-friendly, something that is becoming more important to businesses and customers alike. This water-based ink type contains minimal levels of volatile organic compounds (VOCs) and no hazardous air pollutants, meaning that it is odourless and kinder to the environment, contributing to safer, healthier air.

Heat is used to cure the ink, but it does so more efficiently than other ink options. Again, less electricity is used by the dryer system as it’s very good at retaining heat and optimising drying time.

Roland DG’s advanced RIP software, VersaWorks 6 includes nesting options which optimise media usage too, so waste is kept to a minimum. Sustainability is a concern for everybody and everything we can do to reduce our footprint will benefit the industry and the environment.

Conclusion

The technical excellence of Resin/Latex ink printing means that it’s a straightforward, flexible, and profitable method of creating customised vehicle wraps. The TrueVIS AP-640 Resin/Latex printer makes the most of the innovation in ink technology, offering print businesses the tools they need to create exceptional, durable wraps. From vibrant colour reproduction to unparalleled durability, the benefits of Resin/Latex ink printing are evident across every aspect of vehicle wrapping.

For a print business looking to differentiate itself and explore new growth opportunities, investing in the TrueVIS AP-640 is a strategic move towards prominence in vehicle customisation.

Visit our product page if you’d like more information on the TrueVIS AP-640 resin printer.

Or if you’d like more information on anything we’ve covered in this article, please contact a Roland DG product expert here.