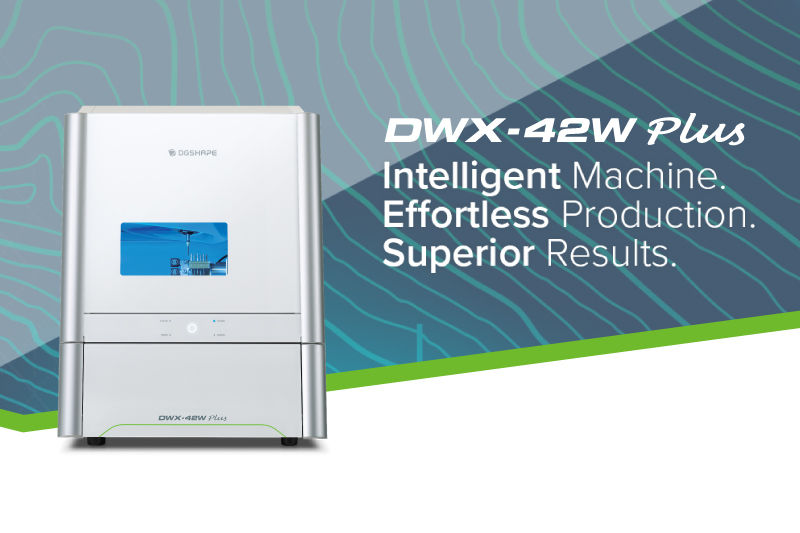

DWX-42W Plus Wet Dental Mill

The DGSHAPE DWX-42W Plus enables wet milling of popular glass ceramic and composite resins with high precision and accuracy.

- High speed production with proprietary DGSHAPE spindle

- Expanded 6-tool Automatic Tool Changer for uninterrupted milling

- Included VPanel for easy monitoring of milling jobs and tools

Incredibly Accurate, High Aesthetic Restorations

A Mill That Fits Your Needs

High Production Lab

- Expand production by adding a standalone wet-milling option, designed for glass ceramic and composite resin materials

- Get the same open architecture flexibility and high-quality performance as DGSHAPE dry mills, in a wet-milling configuration

- Offer on-demand production of high-aesthetic, dental prosthetics

![]()

In-Clinic Lab

- Offer your patients a same day service with ultra-accurate prosthetics – produced with an easy-to-operate machine and simplified workflow

- Open architecture allows seamless integration with existing scanning devices

![]()