Over the past few years, direct‑to‑film (DTF) printing has reshaped how custom apparel is produced, with businesses across Australia increasingly adopting it alongside, or instead of, traditional methods such as screen printing and dye‑sublimation.

DTF printing enables cost‑effective production of vibrant, durable designs on demand, giving printing businesses, garment decorators, and apparel brands the flexibility to serve more customers, diversify revenue streams, and improve profit margins.

According to industry research, the Australian DTF printing market is growing rapidly, with revenue expected to rise from around AUD 87.2 million in 2025 to AUD 127.5 million by 2030 - a compound annual growth rate of about 7.9 per cent. Dedicated DTF printers, especially roll‑to‑roll models like the Roland DG TY‑300, are the fastest‑growing segment as demand increases.

Sports jersey, printed using DTF technology

Why Australian Businesses Are Embracing DTF

Many printing businesses and custom apparel operations in Australia have historically outsourced garments or avoided apparel decorations altogether, due to the high investment and skill required for screen printing or dye‑sublimation. DTF technology changes that.

DTF is:

- Versatile: It prints on almost any fabric - cotton, polyester, denim, nylon, rayon and more - including both light and dark materials.

- Easy to learn: The workflow and skill level are similar to printing decals or other digital graphics.

- Efficient: On‑demand production reduces reliance on large inventories and lowers waste.

This versatility lets printing businesses expand into new markets like sportswear, workwear, branded merchandise, and event apparel - revenue opportunities some were previously missing out on.

TY-300 Direct-to-Film Printer

Measurable ROI for DTF Printing in Australia

While Return on Investment will vary depending on your product mix, pricing, and customer base, many business owners experience strong returns when DTF printing is priced strategically and integrated into a broader service offering.

For example:

Desktop DTF systems (suitable for lower volume and start‑ups) can generate strong margins on everyday custom jobs.

Production‑level DTF printers like the Roland DG TY‑300 - offering high throughput, reliable performance, and low running costs - enable significantly higher revenue potential. Designed for continuous, high‑volume production, these systems help Australian printing businesses scale operations, take on larger contracts, and respond quickly to on‑demand orders.

With improved productivity and quick turnaround times, printing businesses can capture higher‑value jobs from sports teams, schools, corporate clients, and fashion labels that need premium, durable prints.

DTF printing produces stunning results on dark and light fabrics

Materials, Durability and Customer Satisfaction

DTF prints offer excellent durability and wash resistance, making them suitable for everyday wear - one of the key selling points for customers. Unlike dye‑sublimation, DTF works on dark fabrics and produces bold, vibrant prints that stand up to repeated wear and washing.

This durability not only keeps customers happy but also reduces remakes - an often hidden cost in apparel production.

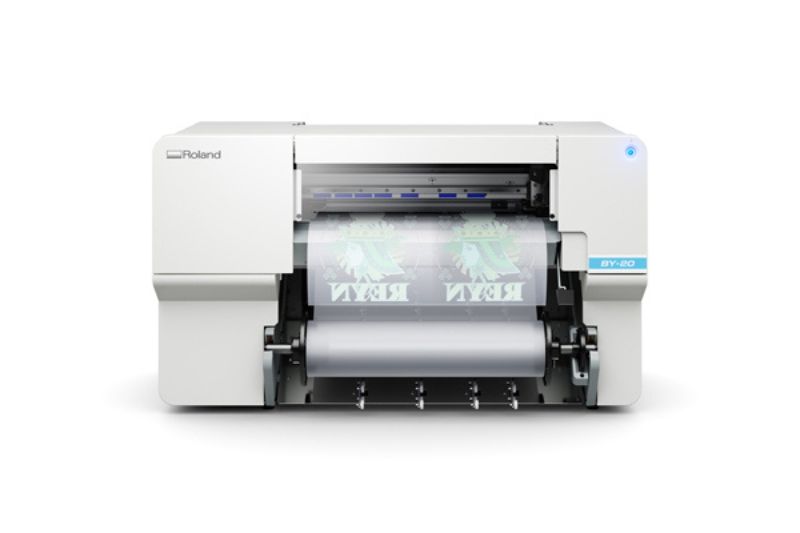

VersaSTUDIO BY-20 Desktop DTF Printer

What to Consider When Evaluating DTF Equipment

When assessing DTF systems for your business, consider these essential factors:

- Production throughput - How many garments can you realistically produce in a day or week? Larger operations, or those fulfilling wholesale or retail contracts, should consider production machines like the TY‑300, whereas smaller operators may start with desktop solutions.

- Running costs - Efficient ink usage, simplified maintenance, and integration with RIP software and support networks help lower day‑to‑day operating expenses. Roland DG’s DTF ecosystem is designed for productivity and cost‑effective workflow management.

- Space and power requirements - Desktop systems need a minimal footprint; production printers like the TY‑300 require more space and can integrate with optional shaker/heater units for automated powder application.

- Support and Warranty - Choose reputable equipment that comes with local support, warranty coverage, and dealer expertise. Roland DG backs its products with industry-leading Warranty and a strong network of authorised Dealers and support technicians across Australia.

Tote Bag printed using DTF technology

Sustainability and Future Outlook

DTF printing supports on‑demand production, meaning businesses can reduce wasted inventory and lower their environmental impact compared with traditional bulk printing. Customers only get what they need, when they need it - a model that aligns with increasing consumer expectations around sustainability.

Looking ahead, the DTF market in Australia is expected to continue expanding as more printing businesses integrate DTF into their workflows. As technology evolves, these systems will become even more intuitive, efficient, and profitable.

Our downloadable Guide to DTF Printing

Conclusion: Growth, Profit, and Competitive Advantage

DTF printing is no longer just a trend - It’s a proven revenue stream for Australian apparel producers and printing businesses. With the right equipment, workflow, and market positioning, you can tap into rising demand, boost margins, and future‑proof your business.

Download our FREE DTF Printing Guide, developed to help you take the next step into DTF Printing and unlock new possibilities.

If you’d like to explore how Roland DG’s DTF solutions can help your business grow, our team can walk you through options tailored to your goals and production needs. Contact us today.