A CHEAT SHEET FOR COMMONLY USED PRINTING TERMS

If you’re just starting out in print, bought your first Roland DG device, or you’re just interested to learn more about common print terms, this cheat sheet is for you. It will allow you to identify and help you get familiar with the commonly used terms that print professionals use:

Die Cut (Perforated Cut or Perf Cut)

A cutting process that results in each sticker being cut into the shape of the image — including the liner or backing paper.

Kiss Cut (Contour Cut)

A print process in where each sticker is cut on a sheet of multiple stickers to leave the liner or backing paper still intact — allowing you to peel each sticker off individually from the liner.

Colour Gamut

A term that refers to the range of colour that a printer can produce. Some printers have “wide colour gamuts” — meaning they can reproduce a wider variety of colour hues, different black tones, and reproduce smooth colour transition without visible colour separation.

Spot Colours

Specific colour choices you can apply to graphics in your design software— similar to a paint colour swatch that has a variety of “spot” colour options. For example, Coca Cola has its own spot colour for Coca Cola red and Jetstar has a specific spot colour for Jetstar orange. Most brands use spot colours to define the exact colour for their logos to ensure they get the consistent colour they want on their branded promotions and graphics.

Vector Files

File types typically created in CorelDRAW® or Adobe Illustrator® which are scalable to any size, and commonly saved as eps or pdf files. It is often the preferred file type for printing because you can enlarge vector elements without degrading the image quality. You can also easily assign spot colours to vector shapes when creating vector files.

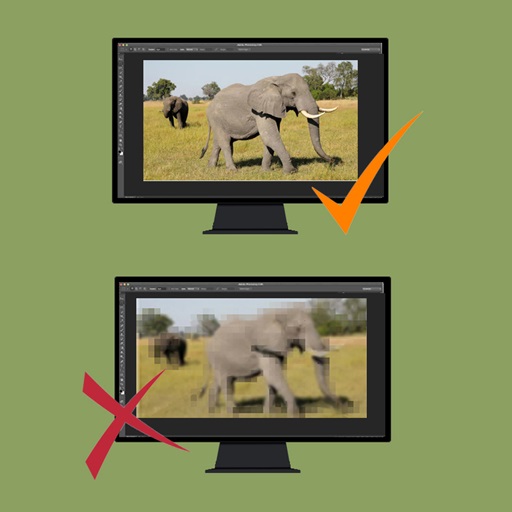

Raster Files

A file type often created in Adobe Photoshop and saved as a .jpeg, .png, and .pdf photo file. Raster files contain pixels that make up the image you design or take with your camera. Large files taken with high-resolution cameras or designed as high-resolution files are commonly scaled up to use in wide format print applications, however, low-resolution images cannot scale-up without them looking “pixelated”. The image above is an example of a crisp raster image compared to a pixelated raster image.

DPI

Dots per inch (DPI, or dpi) is a measurement of raster file image quality and refers to the image’s “dot density”. The higher the dot density, the higher file resolution. Web images and smaller images are commonly around 72 dpi in resolution, while images for print are typically 300 dpi and higher. Note: very large print images for billboards and wall graphics often have a smaller dpi to limit file size.

Spot UV Effects

A term referring to different printed special effects using UV ink, such as “UV embossing”, “spot varnishing”, “digital UV embossing”, “3D print embossing” and other effects. In UV inkjet printers, a clear (or gloss) UV ink is directly printed to a specific area of a sign, product or substrate with multiple clear ink passes to create the effect of a varnish or emboss. The more ink passes, the more prominent the raised text, texture, or design element. Available on Roland DG’s UV printers as a matte ink finish or gloss ink finish, it can also be used to quickly and effectively create braille on signage as well.

RIP Software

This is the software that processes your designs for outputting with a printer. RIP stands for Raster Image Processor. When you purchase a printer from Roland DG, the RIP software is included – typically Roland DG’s VersaWorks 6 or other related production program. Using this software, you can import an image created in your design software into your RIP software for print output. RIP software communicates directly with your printer to instruct it what to print — translating the data from .pdf, .eps, .jpg, etc. into the ink droplets your printer will output.

Design Software

The term “design software” refers to software programs that are used to create your graphics. Commonly used design software programs include CorelDRAW, Adobe Illustrator, and Adobe Photoshop.

Gradients

Created in your design software program, this term refers to the colour transitions from one colour to another — often from light-to-dark colour in an “ombre effect.” Printers, such as TrueVIS printers with wider colour gamuts, yield smoother gradients that don’t have visible colour transitions from one colour to another.

Colour Profiles

Each combination of printer and material type has its own ink recipes to get the best results. A colour profile is a pre-determined “colour space” created to use in your design and print output, to ensure predictable colour results with that printer and substrate. Colour profiles communicate the sequence and levels of ink colours for outputting in your RIP software, in order to achieve your desired colour.

Over-laminate

This is a protective, adhesive clear film that’s removed from its liner and applied to printed graphics to help them last longer and prevent damage. It’s typically applied to your printed graphics with a laminating device.

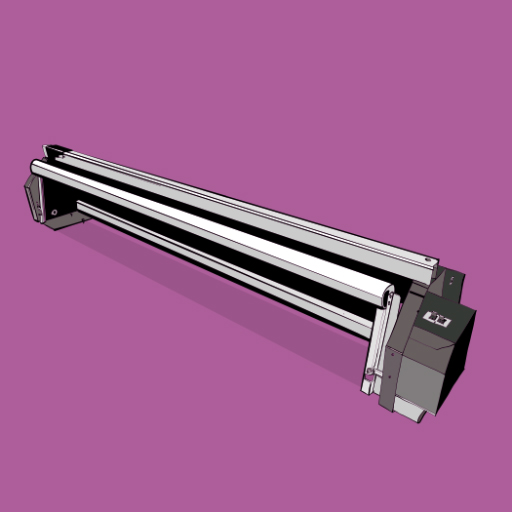

Take-Up Reel

A take-up reel attaches to the front of your printer at its base to neatly roll-up the printed vinyl, paper, or other material as it comes off your printer — keeping the material off the floor. Smaller desktop printers do not have them. A controller and a sensor on the take-up reel work together to automatically roll up your printed material.

Tunneling

This is not a fun word for a print pro – referring to the printed media shifting or “skewing” its movement towards one end of the media roll. It can largely be avoided with proper set-up of Roland DG equipment known for “non-skew” production, but it can be very frustrating for printing or laminating when the media needs to move through these devices at a precise angle.

Popping the Laminator

This is what a laminator operator does when tunneling of the media is causing wrinkles on a print project. “Popping” simply means hitting the roller release just long enough to pull the media and the over-laminate taut through the laminator to remove the wrinkles.

Eco Solvent Ink

A type of ink used with Roland DG printers that has minimal odour and can be used in indoor and outdoor applications. The term “eco-solvent” refers to the low VOC level, or low solvent oil concentrate in the inks. The latest TrueVIS TR2 eco solvent inks offer exceptional colour results.

CC

This stands for “cubic centimetre” and is commonly used as the unit of measurement for volume of ink. It is also equivalent to millilitre, or ml for short.